TECHNOLOGY & TOOLS

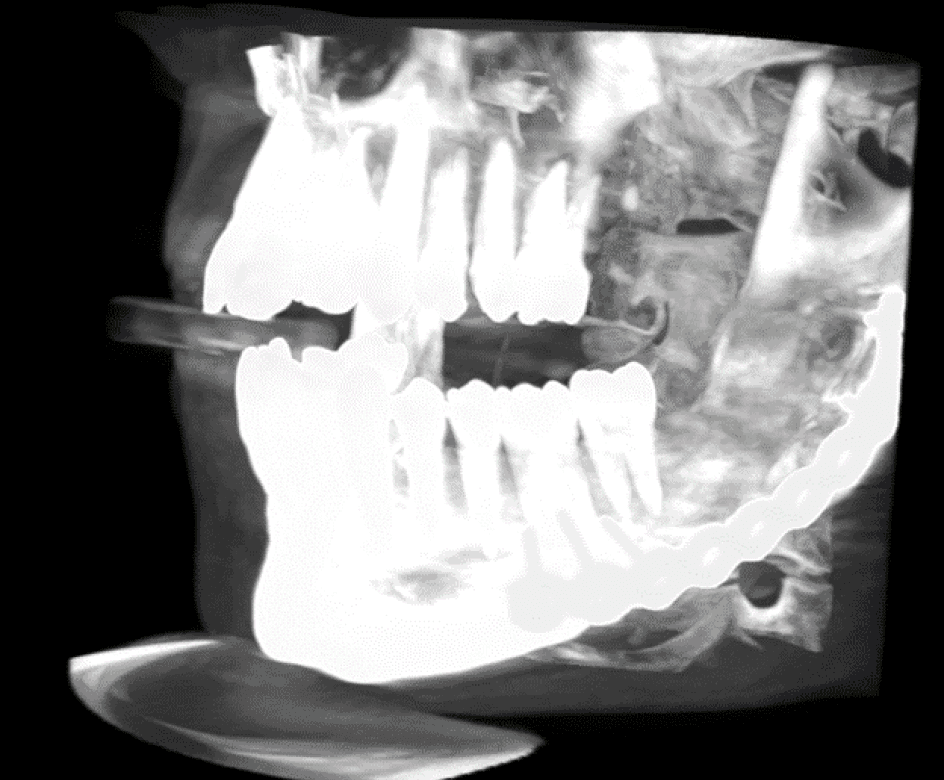

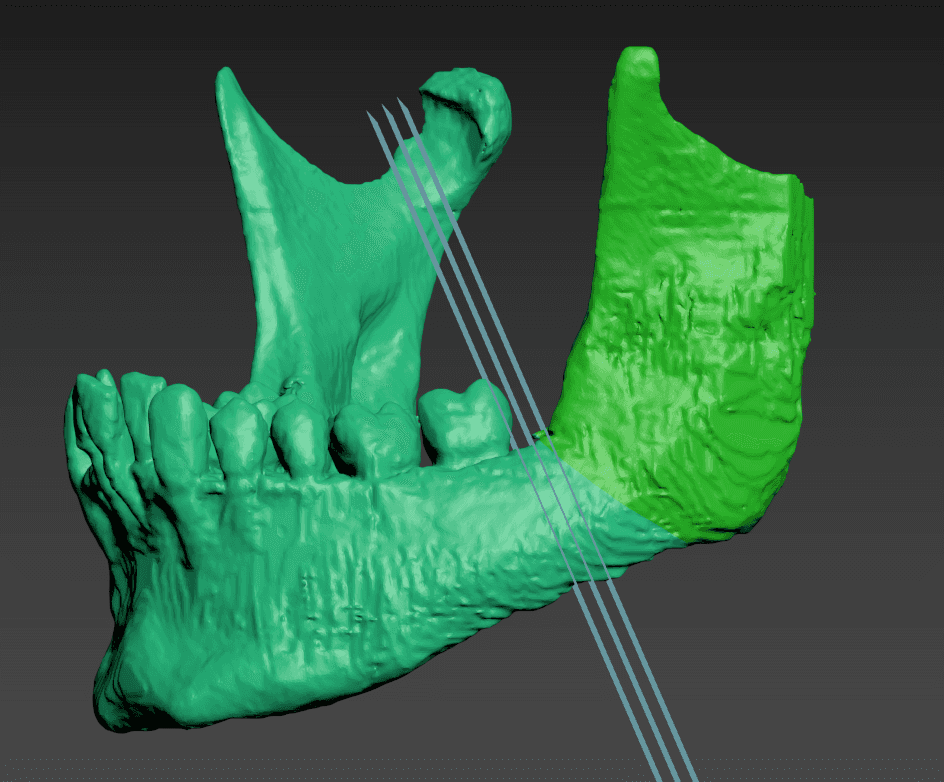

In the initial phase of our investigative process, we meticulously gather detailed information about the injuries sustained by the individuals involved in the accident. This data collection involves thorough examination of medical reports, imaging scans (such as MRI or CT scans), and other reports from medical professionals. By compiling comprehensive information about the injuries, we ensure that our 3D printed models accurately represent the specific anatomical structures and injury patterns.

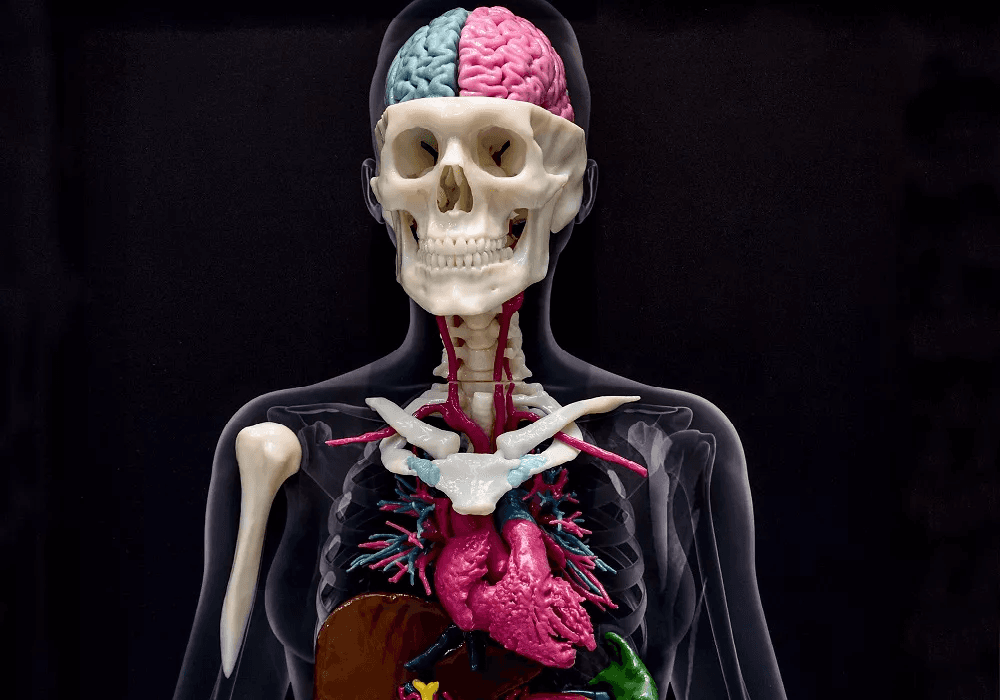

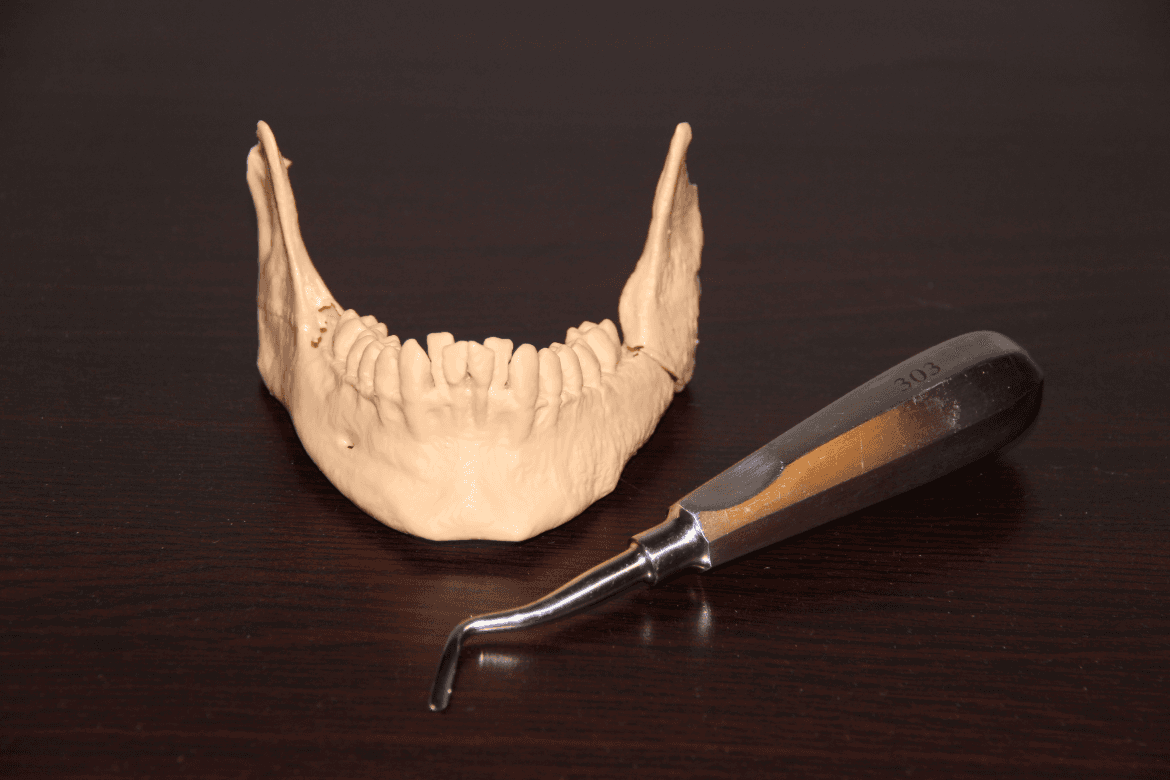

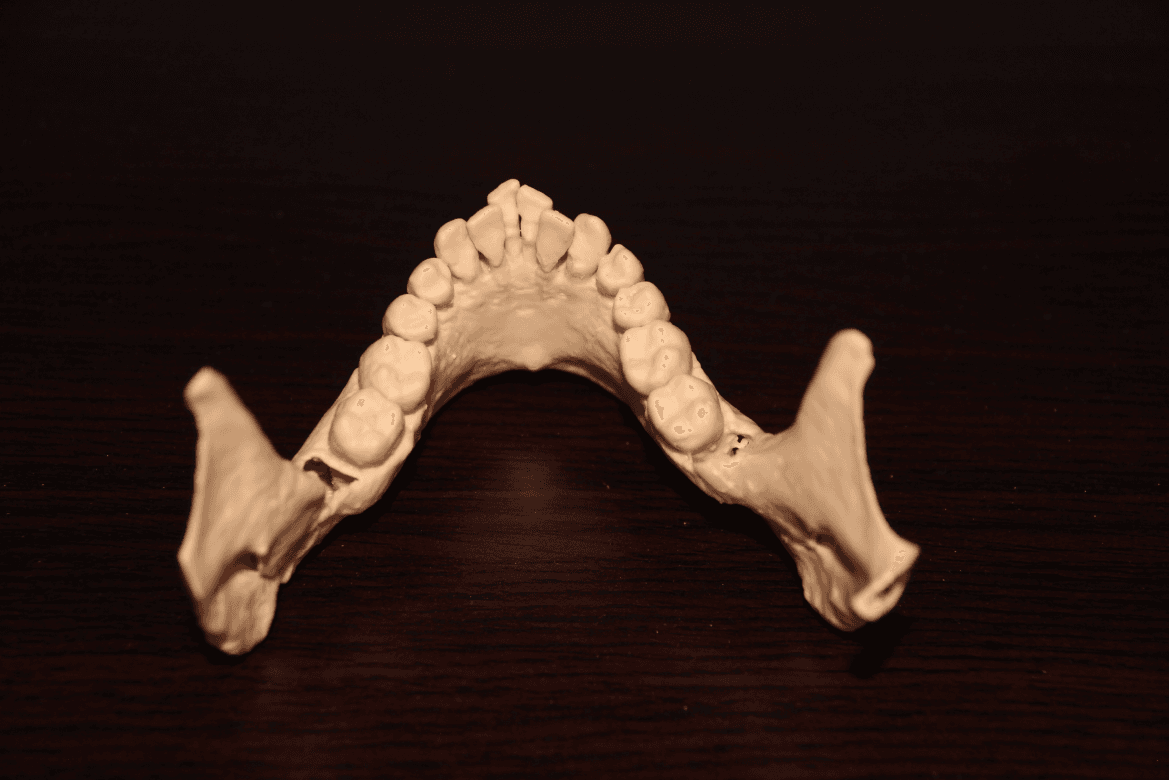

Once the 3D printed injury models are produced, they facilitate further analysis to identify key factors such as impact points, force distribution, and injury patterns. Our team of experts examines the physical models to extract valuable insights into the injury causation and severity. These findings are then presented in compelling visual formats, incorporating detailed explanations and annotations to support a clear understanding of what happened to the damaged tissues. Whether used in courtroom presentations, mediation sessions, or investigative reports, our 3D printed injury models serve as powerful tools for conveying complex medical information in a comprehensive and understandable manner.

In addition to being used to inform reconstruction and biomechanics efforts, our 3D medical prints are ideal for firms designing medical devices. Our anatomical models can be tailor-made to provide device engineers a remarkable tool with which to test during product development or testing.

Once the data collection phase is complete, we employ advanced printing technologies to reconstruct the injuries based on the collected Digital Imaging and Communications in Medicine (DICOM) data. This reconstruction process involves creating precise three-dimensional models of the injured or subject anatomy, making details such as the location, extent, and injury severity more accessible. These 3D models can be made with a variety of materials and stiffnesses to suit clients’ needs.