Motorcycle Sliding Deceleration: Unraveling the Drag Factor

Motorcycle Sliding Deceleration: Unraveling the Drag Factor

Michael McCort, P.E.

Michael McCort, P.E.

Motorcycle Sliding Deceleration Comparison of Test Results

Over the years, many studies have been performed by various authors to determine the rate at which a motorcycle which is sliding on its side will slow down. Deceleration rate is an important variable when determining speed in the reconstruction of a motorcycle crash. For this article, the term “drag factor” will be used to describe the effective slowing deceleration of a motorcycle as it slides or tumbles along the ground surface.

As part of ongoing investigations into motorcycle crashes, CCE has compiled data from studies of drag factor for a motorcycle sliding on its side. At the time of this writing, 14 studies published over 36 years dating back to 1984 have been compiled. When grouped by parameters such as those described below, the combined studies produced more than 70 results or ranges of results. A matrix of data compiled from the studies can be downloaded below and a list of the studies included in the compilation can be found at the bottom of this article.

Most of the referenced studies include a review of previous research. The intent of this article is to provide a useful “quick reference” tool for investigators interested in the subject. The matrix is a great place to start when trying to arrive at an appropriate value for drag factor. The matrix should not be used as a stand along resource and is intended to point the user to the available research on the subject. The reader is encouraged to use the matrix as a starting point and general guide and to reference the actual studies for more details.

Motorcycle Sliding Deceleration Comparison of Test Results

Over the years, many studies have been performed by various authors to determine the rate at which a motorcycle which is sliding on its side will slow down. Deceleration rate is an important variable when determining speed in the reconstruction of a motorcycle crash. For this article, the term “drag factor” will be used to describe the effective slowing deceleration of a motorcycle as it slides or tumbles along the ground surface.

As part of ongoing investigations into motorcycle crashes, CCE has compiled data from studies of drag factor for a motorcycle sliding on its side. At the time of this writing, 14 studies published over 36 years dating back to 1984 have been compiled. When grouped by parameters such as those described below, the combined studies produced more than 70 results or ranges of results. A matrix of data compiled from the studies can be downloaded below and a list of the studies included in the compilation can be found at the bottom of this article.

Most of the referenced studies include a review of previous research. The intent of this article is to provide a useful “quick reference” tool for investigators interested in the subject. The matrix is a great place to start when trying to arrive at an appropriate value for drag factor. The matrix should not be used as a stand along resource and is intended to point the user to the available research on the subject. The reader is encouraged to use the matrix as a starting point and general guide and to reference the actual studies for more details.

Variables in the Studies

When considering the studies in the matrix, the reader will find drag factors ranging from as low as 0.26 to as high as 1.2. One reason for the wide range in results is the range in variables introduced in the individual studies. An understanding of the underlying details of the studies is critical to proper application of available data so that an “apples to apples” comparison can be made to the investigation of a crash. Variables such as the test methodology, test surface, type of motorcycle, equipment on the motorcycle and test speed may all affect the results. Some of the referenced studies examined the sensitivity of variables to the outcome of the test. Carter et. al [4] observed some speed effects in his work, with higher test speeds producing a lower drag factor. Intuition is not a scientific method and can sometimes be wrong. For example, sport and sport touring motorcycles often have frame sliders installed to protect damage to plastics/fairings and the frame in the event of a crash. One might think that a “slider” would reduce the drag factor of a sliding motorcycle. To the contrary, Peck et. al [10] found that sport bikes equipped with frame sliders had a higher drag factor. Before arriving at “THE drag factor number” to be used in an analysis, the reader should carefully evaluate how the test was performed and determine if the resulting data applies to the crash being studied.

Test Methodologies

Various methodologies were used by the authors of the studies to determine sliding drag factor for a respective test or series of tests. The methodologies used can generally be broken into two categories (with one exception1): drag tests and drop tests. Drag tests typically involved pulling a motorcycle that was already laying on its side at a slow speed while measuring the force required to pull it. Drop tests involved dropping the motorcycle from a moving test fixture. Motorcycles were dropped from an upright position to simulate the “capsize” portion of the crash. In some tests, motorcycles were dropped from a horizontal position. Drop tests were not always used strictly to determine an overall average drag factor. Some authors specifically studied capsize portion of the crash. Generally speaking, capsize drop tests resulted in higher drag factors due to the spike in deceleration at the moment the motorcycle struck the ground. The test matrix can be sorted by the test methodology type.

Test Speeds

The speeds tested ranged from 6 mph to 60 mph. Drag tests were generally performed at slower speeds. Drop tests that were designed to more closely simulate a motorcycle falling from its wheels to the ground were generally the tests that were run at the highest speeds. Drop tests where motorcycles were already horizontally oriented tended to be run at mid-range speeds. The test matrix can be sorted by test speeds.

Motorcycle Types

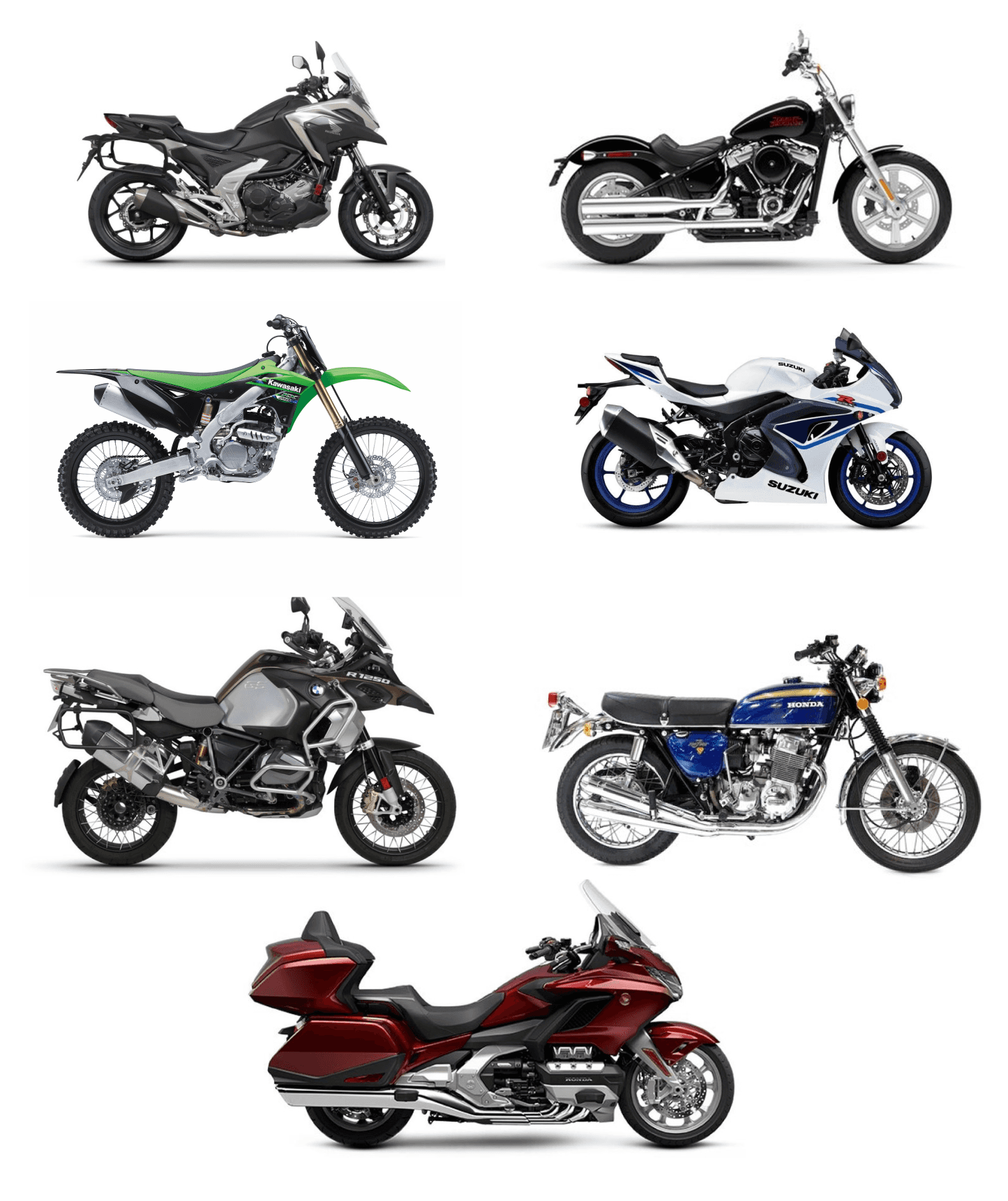

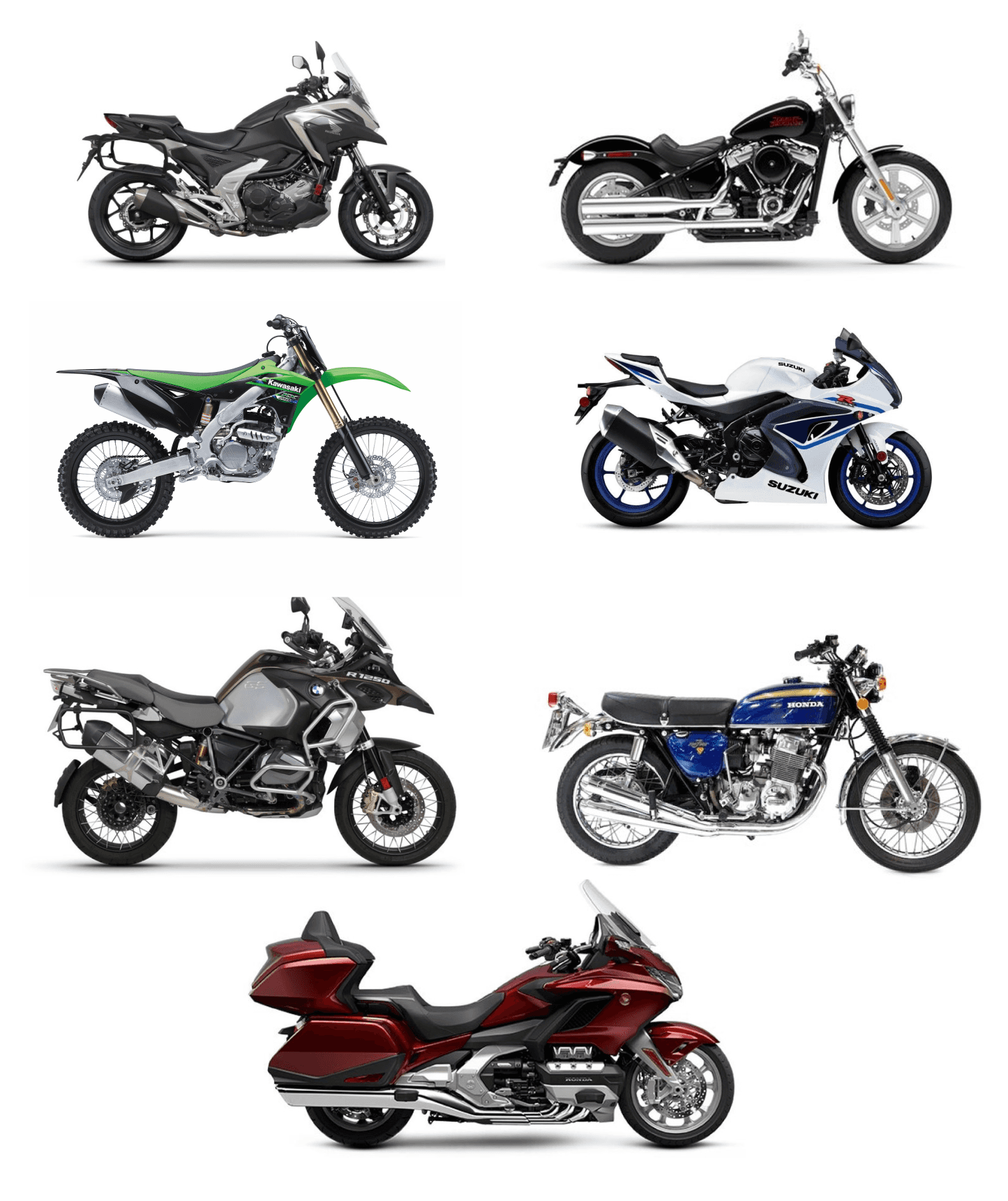

Various types of motorcycles were used in the testing and the matrix can be sorted by type. The older studies tended to use a standard motorcycle, sometimes called a Universal Japanese Motorcycle (UJM). Other motorcycle types tested were sport, sport touring, cruiser, motocross and moped.

Test Surface

he overwhelming majority of motorcycle side sliding tests were performed on paved concrete or asphalt surfaces. There is extremely limited data for motorcycles sliding on grass or dirt and there is a need for more studies to quantify the effect of these surfaces. Day and Smith [1] performed a single drag test on one side of a 1967 Honda CB305 motorcycle on grass. Bartlett [7] performed one test where a motorcycle was dropped on “hardpack dirt” and a second test where a motorcycle was dropped on “grassy soil”. Carter [4] conducted 50 tests but only 2 tests on dirt and 2 tests on gravel. Two of the tests run by Medwell [5] resulted in the motorcycle sliding from the paved surface onto grass before it came to rest. Using data from other tests, Medwell performed an analysis to approximate the drag factor on grass. The matrix can be sorted by surface type.

Motorcycle Equipment

Various authors have found equipment on motorcycles such as crash bars, fairings, and frame sliders have an effect on drag factor. For example, Raftery [3] specifically studied the effect of fairing equipped motorcycles and concluded the drag factor was lower that with fairing removed. Carter [4] reached a similar conclusion. Motorcycle equipment is listed in the Special Conditions column of the matrix.

References

Day, T. and Smith, J., “Friction Factors for Motorcycles Sliding on Various Surfaces,”840250, Society of Automotive Engineers, 1984

Lambourn, R., “The Calculation of Motorcycle Speeds from Sliding Distances”, 910125, Society of Automotive Engineers, 1991

Raftery, B, “Determination of the Drag Factor of a Fairing Equipped Motorcycle”, 950197, Society of Automotive Engineers, 1995

Carter, T., Enderle, B., Gambardella, C., Trester, R., “Measurement of Motorcycle Slide Coefficients”, 961017, Society of Automotive Engineers, 1996

Medwell, C., McCarthy, J., Shanahan, M., “Motorcycle Slide to Stop Tests”, 970963, Society of Automotive Engineers, 1997

Hague, D., “Calculation of Speed from Motorcycle Slide Marks. Estimation of Deceleration Rate from Published Data”

Bartlett, W., Baxter, A., Robar, N., “Motorcycle Slide-to-Stop Tests :I.P.T.M. Data Through 2006”, Accident Investigation Quarterly, Issue 46, Spring, 2007

McNally, B., Bartlett, W., “Motorcycle Sliding Coefficient of Friction Tests”, Presented at the 21st Annual Special Problems in Accident Reconstruction held at the Institute of Police Technology and Management, Jacksonville, FL.

Published in the Accident Investigation Journal, Vol. 17, Iss. 2, 2007, pp. 47-49Walsh, D., Wood, D., Alliot, R., Glynn, C., Simms, C., “Motorcycle Capsize Mechanisms and Confidence Limits for Motorcycle Capsize Speeds from Slide/Bounce Distance”, The Institute of Traffic Accident Investigators, 9th International Conference held at Hinkley Island – September 2009

Peck, L., Focha, B., Gloekler, T., “Motorcycle Sliding Friction for Accident Investigation”, Proceedings of the 10th International Motorcycle Conference, Institute for Motorcycle Safety, Essen, Germany, pp. 62-78, 2014.

DiTallo, M., Munyon, B., Green, T., Paul, E., Adamson, K., Merolli, M., Vosburgh, K., Cox, B., Anderson, R., Hallman, D., Moody, E., Whelan, J., “3 Different Methodologies for Determining the Drag Factor for Motorcycles Sliding on their Sides”, Collision Magazine, Vol 12, Issue 1

Rose, N., Palmer, P., Smith, C., Carter, N., Walter, K., “Decelerations of Capsized Motorcycles – An Update”, SAE 2022-01-0823

Variables in the Studies

When considering the studies in the matrix, the reader will find drag factors ranging from as low as 0.26 to as high as 1.2. One reason for the wide range in results is the range in variables introduced in the individual studies. An understanding of the underlying details of the studies is critical to proper application of available data so that an “apples to apples” comparison can be made to the investigation of a crash. Variables such as the test methodology, test surface, type of motorcycle, equipment on the motorcycle and test speed may all affect the results. Some of the referenced studies examined the sensitivity of variables to the outcome of the test. Carter et. al [4] observed some speed effects in his work, with higher test speeds producing a lower drag factor. Intuition is not a scientific method and can sometimes be wrong. For example, sport and sport touring motorcycles often have frame sliders installed to protect damage to plastics/fairings and the frame in the event of a crash. One might think that a “slider” would reduce the drag factor of a sliding motorcycle. To the contrary, Peck et. al [10] found that sport bikes equipped with frame sliders had a higher drag factor. Before arriving at “THE drag factor number” to be used in an analysis, the reader should carefully evaluate how the test was performed and determine if the resulting data applies to the crash being studied.

Test Methodologies

Various methodologies were used by the authors of the studies to determine sliding drag factor for a respective test or series of tests. The methodologies used can generally be broken into two categories (with one exception1): drag tests and drop tests. Drag tests typically involved pulling a motorcycle that was already laying on its side at a slow speed while measuring the force required to pull it. Drop tests involved dropping the motorcycle from a moving test fixture. Motorcycles were dropped from an upright position to simulate the “capsize” portion of the crash. In some tests, motorcycles were dropped from a horizontal position. Drop tests were not always used strictly to determine an overall average drag factor. Some authors specifically studied capsize portion of the crash. Generally speaking, capsize drop tests resulted in higher drag factors due to the spike in deceleration at the moment the motorcycle struck the ground. The test matrix can be sorted by the test methodology type.

Test Speeds

The speeds tested ranged from 6 mph to 60 mph. Drag tests were generally performed at slower speeds. Drop tests that were designed to more closely simulate a motorcycle falling from its wheels to the ground were generally the tests that were run at the highest speeds. Drop tests where motorcycles were already horizontally oriented tended to be run at mid-range speeds. The test matrix can be sorted by test speeds.

Motorcycle Types

Various types of motorcycles were used in the testing and the matrix can be sorted by type. The older studies tended to use a standard motorcycle, sometimes called a Universal Japanese Motorcycle (UJM). Other motorcycle types tested were sport, sport touring, cruiser, motocross and moped.

Test Surface

he overwhelming majority of motorcycle side sliding tests were performed on paved concrete or asphalt surfaces. There is extremely limited data for motorcycles sliding on grass or dirt and there is a need for more studies to quantify the effect of these surfaces. Day and Smith [1] performed a single drag test on one side of a 1967 Honda CB305 motorcycle on grass. Bartlett [7] performed one test where a motorcycle was dropped on “hardpack dirt” and a second test where a motorcycle was dropped on “grassy soil”. Carter [4] conducted 50 tests but only 2 tests on dirt and 2 tests on gravel. Two of the tests run by Medwell [5] resulted in the motorcycle sliding from the paved surface onto grass before it came to rest. Using data from other tests, Medwell performed an analysis to approximate the drag factor on grass. The matrix can be sorted by surface type.

Motorcycle Equipment

Various authors have found equipment on motorcycles such as crash bars, fairings, and frame sliders have an effect on drag factor. For example, Raftery [3] specifically studied the effect of fairing equipped motorcycles and concluded the drag factor was lower that with fairing removed. Carter [4] reached a similar conclusion. Motorcycle equipment is listed in the Special Conditions column of the matrix.

References

Day, T. and Smith, J., “Friction Factors for Motorcycles Sliding on Various Surfaces,”840250, Society of Automotive Engineers, 1984

Lambourn, R., “The Calculation of Motorcycle Speeds from Sliding Distances”, 910125, Society of Automotive Engineers, 1991

Raftery, B, “Determination of the Drag Factor of a Fairing Equipped Motorcycle”, 950197, Society of Automotive Engineers, 1995

Carter, T., Enderle, B., Gambardella, C., Trester, R., “Measurement of Motorcycle Slide Coefficients”, 961017, Society of Automotive Engineers, 1996

Medwell, C., McCarthy, J., Shanahan, M., “Motorcycle Slide to Stop Tests”, 970963, Society of Automotive Engineers, 1997

Hague, D., “Calculation of Speed from Motorcycle Slide Marks. Estimation of Deceleration Rate from Published Data”

Bartlett, W., Baxter, A., Robar, N., “Motorcycle Slide-to-Stop Tests :I.P.T.M. Data Through 2006”, Accident Investigation Quarterly, Issue 46, Spring, 2007

McNally, B., Bartlett, W., “Motorcycle Sliding Coefficient of Friction Tests”, Presented at the 21st Annual Special Problems in Accident Reconstruction held at the Institute of Police Technology and Management, Jacksonville, FL.

Published in the Accident Investigation Journal, Vol. 17, Iss. 2, 2007, pp. 47-49Walsh, D., Wood, D., Alliot, R., Glynn, C., Simms, C., “Motorcycle Capsize Mechanisms and Confidence Limits for Motorcycle Capsize Speeds from Slide/Bounce Distance”, The Institute of Traffic Accident Investigators, 9th International Conference held at Hinkley Island – September 2009

Peck, L., Focha, B., Gloekler, T., “Motorcycle Sliding Friction for Accident Investigation”, Proceedings of the 10th International Motorcycle Conference, Institute for Motorcycle Safety, Essen, Germany, pp. 62-78, 2014.

DiTallo, M., Munyon, B., Green, T., Paul, E., Adamson, K., Merolli, M., Vosburgh, K., Cox, B., Anderson, R., Hallman, D., Moody, E., Whelan, J., “3 Different Methodologies for Determining the Drag Factor for Motorcycles Sliding on their Sides”, Collision Magazine, Vol 12, Issue 1

Rose, N., Palmer, P., Smith, C., Carter, N., Walter, K., “Decelerations of Capsized Motorcycles – An Update”, SAE 2022-01-0823

LET’S WORK TOGETHER

We’re looking forward to hearing how we can help.

Call our office at 720-458-9190 or click below.

TELL US ABOUT YOUR CASE

LET’S WORK TOGETHER

We’re looking forward to hearing how we can help.

Call our office at 720-458-9190 or click below.

TELL US ABOUT YOUR CASE

LET’S WORK TOGETHER

We’re looking forward to hearing how we can help.

Call our office at 720-458-9190 or click below.

TELL US ABOUT YOUR CASE

Corporate Headquarters

Compass Consulting Engineers PC

10875 Dover St., # 900 Westminster, CO 80021

Pacific Northwest Region

Compass Consulting Engineers PC

13036 SE Kent-Kangley Rd, Suite 7, Kent, WA 98030

Canadian Region

Compass Consulting Engineers Inc.

1975 McCallum Road, Unit 115 #1029, Abbotsford, BC V2S 3N3

Corporate Headquarters

Compass Consulting Engineers PC

10875 Dover St., # 900 Westminster, CO 80021

Pacific Northwest Region

Compass Consulting Engineers PC

13036 SE Kent-Kangley Rd, Suite 7, Kent, WA 98030

Canadian Region

Compass Consulting Engineers Inc.

1975 McCallum Road, Unit 115 #1029, Abbotsford, BC V2S 3N3

Corporate Headquarters

Compass Consulting Engineers PC

10875 Dover St., # 900 Westminster, CO 80021

Pacific Northwest Region

Compass Consulting Engineers PC

13036 SE Kent-Kangley Rd, Suite 7, Kent, WA 98030

Canadian Region

Compass Consulting Engineers Inc.

1975 McCallum Road, Unit 115 #1029, Abbotsford, BC V2S 3N3